Anode Materials Process Optimization Consulting

Maximize yield, reduce costs, and achieve superior performance in synthetic graphite, natural graphite, and silicon-graphite composite production. Expert optimization from Delta3CoreTec's battery materials specialists.

30%

Yield Improvement

25%

Cost Reduction

99.95%

Purity Achieved

Anode Materials We Optimize

Synthetic Graphite

Primary FocusGraphitization, purification, spheronization

Natural Graphite

OptimizedBeneficiation, coating, surface treatment

Silicon-Graphite

Next-GenSi content optimization, expansion control

Hard Carbon / Bio Graphite

SpecializedPyrolysis optimization, porosity control

Delta3CoreTec's Pilot Process Optimization Methodology

Process Audit

Baseline Assessment

Data Analytics

KPI Identification

Pilot Trials

DOE & Testing

Scale-Up

Implementation

Validation

QA & Control

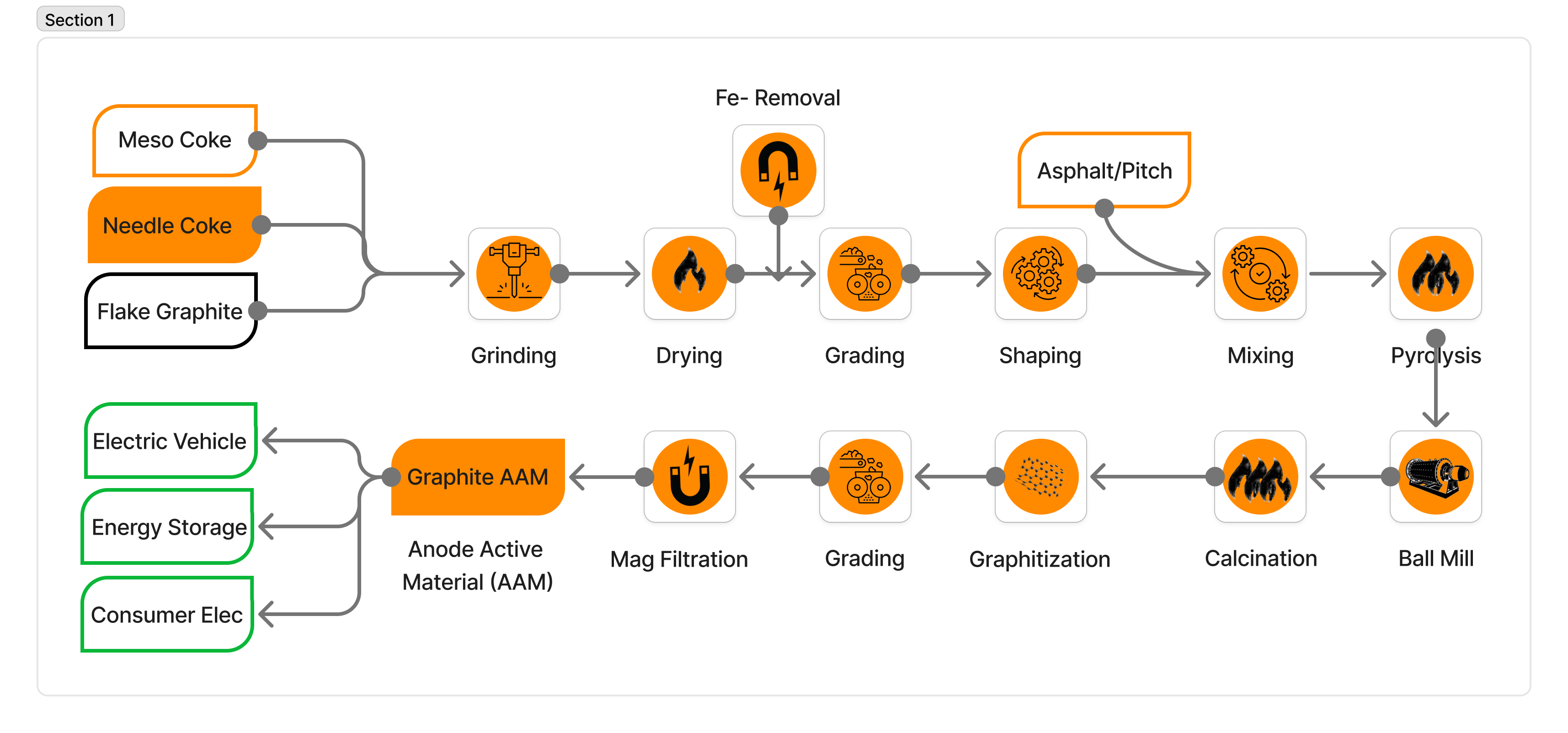

Synthetic Graphite Production Process Flow

Anode Materials Process Optimization Services

Comprehensive optimization consulting to maximize yield, reduce costs, and achieve superior electrochemical performance

Graphitization Process

- • Temperature profile optimization

- • Energy consumption reduction

- • Furnace utilization improvement

- • Crystallinity enhancement

- • Throughput maximization

- • Heat recovery systems

Typical improvement: 20-30% energy savings

Purification & Treatment

- • Chemical purification optimization

- • Thermal purification efficiency

- • Impurity removal strategies

- • Surface modification

- • Coating process improvement

- • Quality control enhancement

Target: 99.95%+ purity consistently

Particle Engineering

- • Spheronization process control

- • Particle size distribution

- • Surface area optimization

- • Tap density improvement

- • D50/D10/D90 control

- • Morphology optimization

Achievement: OEM specification compliance

Silicon-Graphite Composites

- • Silicon content optimization

- • Expansion mitigation strategies

- • Composite structure design

- • Prelithiation techniques

- • Cycle stability improvement

- • First cycle efficiency

Target: 450+ mAh/g capacity

Yield Enhancement

- • Process yield analysis

- • Loss point identification

- • Recovery system design

- • Waste stream valorization

- • Statistical process control

- • Continuous improvement

Typical result: 25-35% yield increase

Cost Optimization

- • Raw material optimization

- • Energy cost reduction

- • Process simplification

- • Equipment utilization

- • Labor efficiency

- • Supply chain optimization

Average savings: 20-30% OPEX reduction

Anode Performance Metrics We Optimize

365

mAh/g

Reversible Capacity

92%

ICE

First Cycle Efficiency

<15

μm

D50 Particle Size

1.1

g/cm³

Tap Density

<5

m²/g

BET Surface Area

99.95

%

Carbon Purity

<50

ppm

Metal Impurities

0.335

nm

d002 Spacing

Anode Process Yield Calculator

Estimate potential improvements in your anode materials production

Optimization Potential Analysis:

Potential Yield

85%

Material Savings

$3M/year

ROI Timeline

6 months

Ready to achieve these improvements?

Schedule Optimization Consultation →Pilot Plant Development & Scale-Up Excellence

Strategic Pilot Plant Optimization Approach

Phase 1: Pilot Plant Design

- • Process flow sheet development based on target specifications

- • Equipment sizing and selection for 100-1000 kg/day capacity

- • Integration of Industry 4.0 monitoring systems

- • HAZOP and safety system design

Phase 2: Process Validation

- • Design of Experiments (DOE) for parameter optimization

- • Mass and energy balance verification

- • Quality control protocol development

- • Customer sample qualification programs

Pilot Plant Performance Targets

95%

Equipment Uptime

< 2%

Quality Variance

85%

First Pass Yield

30%

OPEX Reduction

Advanced Technology Integration

Process Control Systems

SCADA integration, real-time monitoring, and automated control loops for consistent product quality

Data Analytics Platform

Machine learning models for predictive maintenance and quality prediction

Sustainability Systems

Energy recovery, waste minimization, and circular economy implementation

Delta3CoreTec's Pilot Process Optimization Framework

Baseline Characterization & Gap Analysis

Comprehensive evaluation of your pilot plant's current state including material characterization, process mapping, equipment assessment, and identification of gaps versus target specifications. We establish clear KPIs and success metrics aligned with commercial goals.

Statistical DOE & Process Modeling

Design of Experiments (DOE) to identify critical process parameters, develop predictive models using SysCAD and Aspen Plus, and create digital twins for scenario analysis. Machine learning algorithms optimize multi-variable interactions.

Pilot Trial Execution & Optimization

Systematic pilot trials with real-time data collection, iterative process refinement, and rapid cycle testing. Implementation of advanced process control (APC) systems and in-line quality monitoring for immediate feedback and adjustment.

Scale-Up Engineering & Risk Mitigation

Development of scale-up factors and dimensional analysis, equipment specification for commercial scale, process safety and HAZOP studies, and creation of detailed technology packages for full-scale implementation.

Validation & Continuous Optimization

Customer qualification programs, establishment of statistical process control (SPC) systems, implementation of predictive maintenance protocols, and ongoing support for continuous improvement initiatives.

Anode Optimization Success Story

Global Battery Materials Producer: Synthetic Graphite Excellence

Delta3CoreTec led complete optimization of a major synthetic graphite production facility, achieving industry-leading performance metrics and establishing a competitive position against established global producers.

99.95%

Purity achieved

35%

Yield improvement

40%

Energy reduction

100%

OEM qualification

Key Optimization Achievements:

- • Developed proprietary graphitization process reducing energy consumption by 40%

- • Optimized purification process achieving consistent 99.95%+ carbon content

- • Improved spheronization yield from 45% to 80% through process control

- • Reduced production costs by 35% while exceeding OEM specifications

- • Established quality systems achieving zero customer rejections

Strategic Market Focus: Asia-Pacific Opportunities

India: Emerging Battery Materials Hub

Production Incentive Schemes

PLI schemes offering 20% capex support for battery component manufacturing

Strategic Raw Material Access

Proximity to graphite resources and growing domestic EV market

2030 Market Projection

50,000+ MT/year anode material demand expected

Delta3CoreTec Advantage: Supporting pilot plants from 100 kg/day to commercial scale 10,000+ MT/year facilities

Technology Transfer Excellence

Localization Strategy

Adaptation of global best practices to regional conditions

Supply Chain Integration

Development of local vendor ecosystems and quality standards

Workforce Development

Training programs for operators and process engineers

Implementation Timeline: Pilot plant operational in 6-9 months, commercial scale in 18-24 months

Typical Investment Profile for Synthetic Graphite Plants

Pilot Plant

$2-5M

100-500 kg/day

6-9 months to operation

Demo Plant

$15-30M

1-5 MT/day

12-15 months to operation

Commercial Plant

$100-200M

10,000+ MT/year

18-24 months to operation

ROI Timeline: Typical payback period of 3-5 years with optimized processes

Anode Materials Optimization FAQs

What anode materials can you optimize?

We optimize all major anode materials including synthetic graphite, natural graphite, silicon-graphite composites, hard carbon, soft carbon, and lithium metal anodes. Our expertise covers the complete production process from raw materials to final product.

How much yield improvement is typically achievable?

Yield improvements typically range from 20-35%, depending on current process maturity. We've achieved up to 45% yield improvement in some cases through comprehensive process optimization, waste recovery, and quality control enhancement.

Can you help meet specific OEM requirements?

Yes, we specialize in optimizing processes to meet strict OEM specifications for particle size, purity, electrochemical performance, and other critical parameters. We have experience with requirements from major battery manufacturers worldwide.

What's the typical ROI for process optimization?

Most clients see ROI within 6-12 months through yield improvements, energy savings, and quality enhancements. The exact timeline depends on production volume, current efficiency, and implementation scope.

Do you provide ongoing support after optimization?

Yes, we offer ongoing support packages including remote monitoring, periodic audits, troubleshooting support, and continuous improvement programs to ensure sustained optimization benefits.

Optimize Your Anode Materials Production Today

Get expert anode materials process optimization consulting. Increase yield, reduce costs, and achieve superior performance with proven optimization strategies.

30%

Average Yield Gain

25%

Cost Reduction

40%

Energy Savings

6mo

Typical ROI